Contents

- 1 Deep Dive into Fault Tree Analysis: Unveiling the Roots of Failure

- 2 Introduction:

- 3 What is Fault Tree Analysis (FTA)?

- 4 So, how does FTA work its magic?

- 5 Why is FTA a valuable tool?

- 6 From nuclear reactors to toasters, FTA has applications across diverse fields.

- 7 Conclusion:

- 8 Frequently Asked Questions

Deep Dive into Fault Tree Analysis: Unveiling the Roots of Failure

Introduction:

Imagine a complex system, be it a nuclear reactor, a spacecraft, or even a toaster. It hums along, seemingly invincible, until one day it fails. But what if we could predict and prevent such failures? Enter the world of Fault Tree Analysis (FTA), a powerful tool for dissecting the anatomy of failure and nipping it in the bud.

Fault Tree Analysis (FTA) might sound intimidating, but it’s essentially a detective story for systems. This blog post will be your magnifying glass, delving into each step of Fault Tree Analysis in detail, complete with insightful resources to fuel your analysis adventures.

What is Fault Tree Analysis (FTA)?

FTA is like a detective for systems. It starts with an undesired event, the “top event,” like a reactor meltdown or a burnt toast. Then, it delves deeper, tracing the tangled web of events that could lead to that top event. Think of it as a branching tree, where each branch represents a possible cause and the trunk represents the top event itself. Through this analysis, we uncover the root causes—the fundamental flaws that make the system vulnerable.

So, how does FTA work its magic?

1. Defining the Top Event: Imagine a nuclear reactor spewing radiation—that’s your “top event,” the undesired outcome you want to avoid. It could be anything from a malfunctioning toaster to a missed flight; the key is pinpointing the specific event you want to prevent.

2. Building the Tree: Now, picture this event as the trunk of a fault tree. From there, branch out with potential causes—maybe a faulty cooling system, an operator error, or a power outage. These become the “basic events,” the individual contributors to the top event. Use logic gates like “AND” (both events must occur) and “OR” (either event could trigger the top event) to depict their relationships.

3. Analyzing the Tree: Each branch needs a weight—a probability score indicating how likely that event is to occur. Use data, expert judgment, or a combination of both to assign these scores. This quantifies the risk at each level, revealing the most critical contributors to the top event.

4. Taking Action: The analysis is just the beginning! Based on the identified risks, prioritize mitigation strategies. This could involve redesigning components, implementing safety measures, or enhancing operator training. The aim is to nip potential failures in the bud before they have a chance to bloom.

Why is FTA a valuable tool?

- It’s systematic: Fault Tree Analysis provides a structured approach to analyzing complex systems, ensuring nothing gets overlooked.

- It’s visual: The fault tree diagram makes it easy to understand the relationships between causes and the overall risk picture.

- It’s quantitative: By assigning probabilities, FTA helps prioritize risks and make informed decisions about resource allocation.

- It’s proactive: FTA helps identify potential failures before they occur, allowing for preventive measures to be taken.

From nuclear reactors to toasters, FTA has applications across diverse fields.

- Safety engineering: Identifying hazards in your area, like aircraft, nuclear power plants, and other critical systems.

- Process engineering: Optimizing production processes and preventing equipment failures.

- Software development: Detecting potential bugs and vulnerabilities in software systems.

- Healthcare: Identifying risk factors for disease and developing preventive strategies.

Resources to Fuel Your FTA Investigations:

- International Council on Systems Engineering (INCOSE): https://www.incose.org/

- American Institute of Chemical Engineers (AIChE): https://www.aiche.org/

- Center for Chemical Process Safety (CCPS): https://www.aiche.org/topics/process-safety

- National Aeronautics and Space Administration (NASA): https://www.nasa.gov/

- More read: Production Planning And Control

Conclusion:

Remember, FTA is a powerful tool, not a magic spell. It requires critical thinking, a healthy dose of “what if?” scenarios, and the willingness to build your own fault tree diagram. So, grab your metaphorical magnifying glass, delve into the intricate dance of success and failure, and become a master of preventing the inevitable through FTA!

By understanding each step in detail and utilizing the provided resources, you’ll be well on your way to wielding FTA as a powerful weapon in your arsenal of system analysis. Let’s demystify failures together, one tree diagram at a time!

Frequently Asked Questions

1. What are the limitations of the Fault Tree Analysis?

- FTA can be time-consuming and complex for very large systems.

- Quantifying probabilities can be challenging and subjective, especially for rare events.

- Identifying all potential basic events can be difficult, especially for human error factors.

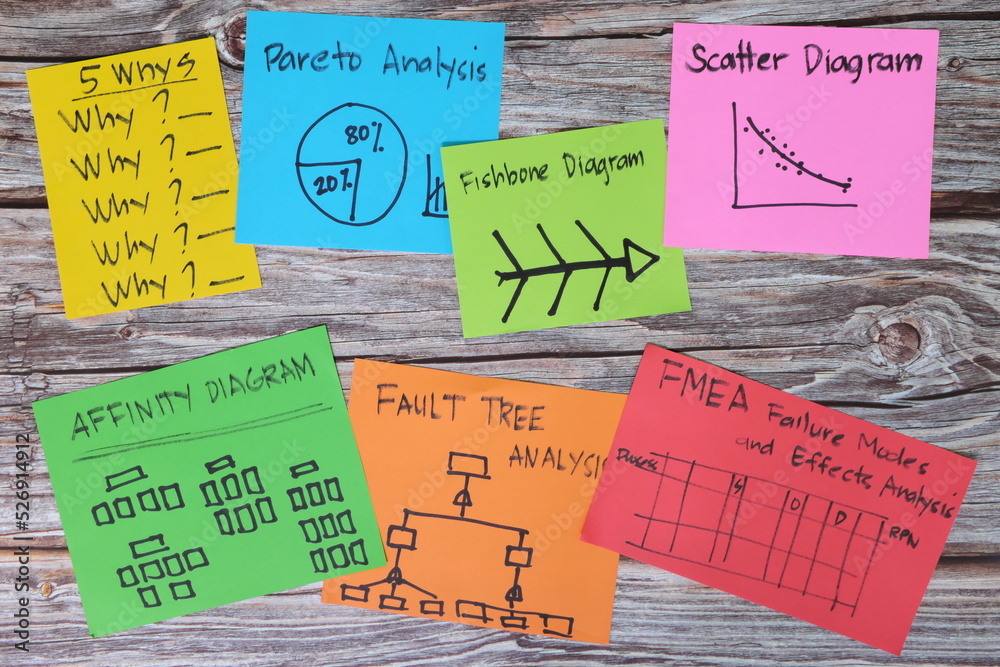

2. What are the alternatives to Fault Tree Analysis?

- Failure Mode and Effects Analysis (FMEA): Focuses on potential failure modes of individual components.

- Hazard Analysis and Criticality Control (HACCC): Used in food safety to identify and control hazards.

- Event tree analysis analyzes the consequences of a specific event rather than its causes.

3. What software tools can I use for Fault Tree Analysis?

- Numerous software tools, like Reliability Workbench, Arborist, and WinFMEA, offer FTA capabilities.

- Spreadsheet software like Excel can also be used for simple FTA models.

4. Where can I get training in Fault Tree Analysis?

- Organizations like INCOSE, AIChE, and CCPS offer training courses on FTA.

- Universities and online platforms also offer educational resources on FTA.

5. Can FTA be used for non-technical systems?

- Absolutely! FTA principles can be applied to analyze processes, organizational structures, and even social systems.